BIM is helping the architectural, engineering, and construction sector digitize itself by lowering project costs while boosting quality and efficiency. BIM produces more precise cost estimates than traditional methods since it is an intelligent, data-rich model that ties specific components to their materials. BIM-based Quantity Takeoff (QTO) can extract the geometric data and semantic properties of architectural elements to determine a quantity. Efficient data management and rapid decision-making have been attained with the AEC sector’s transition from CAD to BIM. The Quantity Takeoff procedure can be automated utilizing BIM workflow as long as the model is built with precise geometry, dimensions, and elemental features.

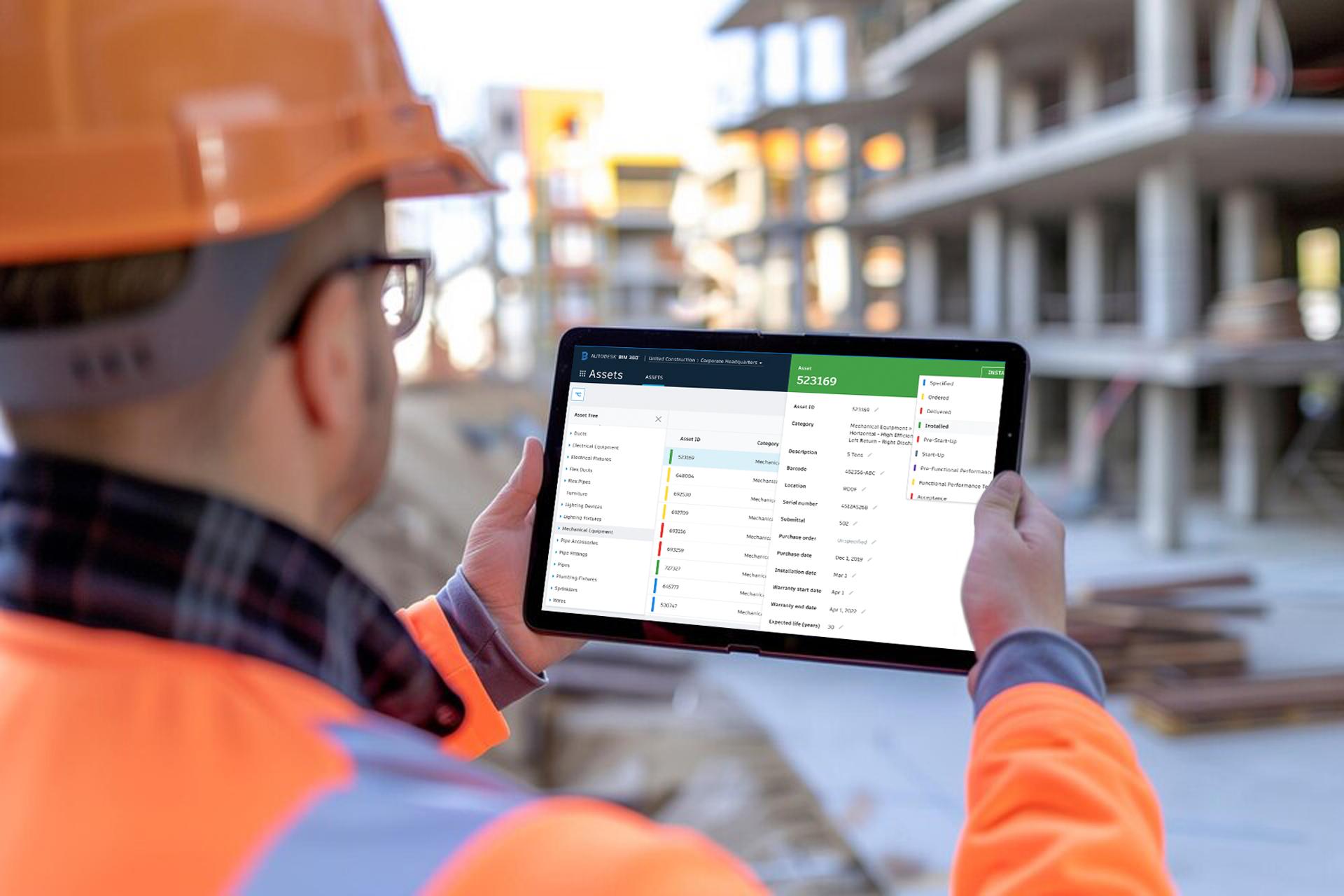

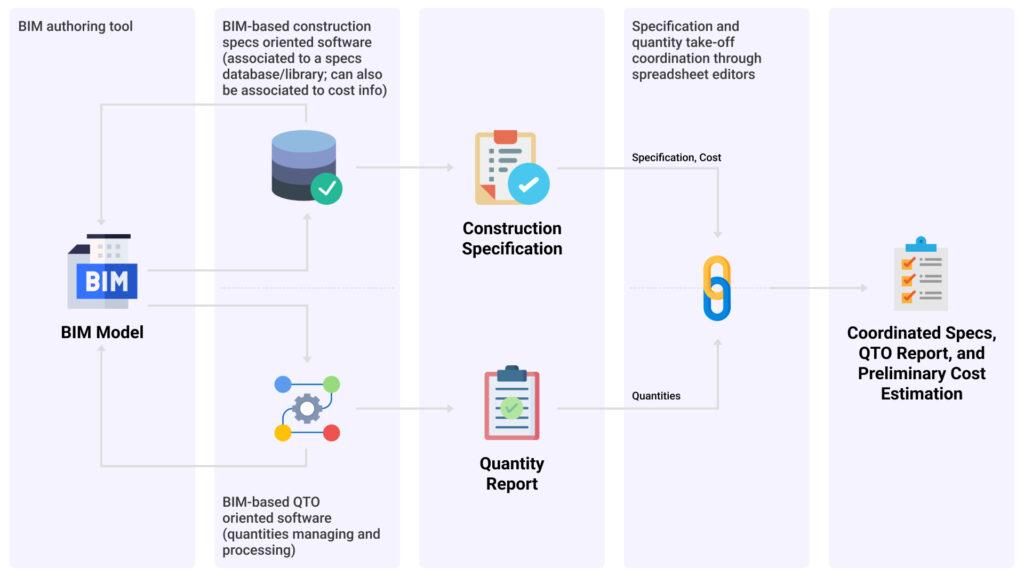

BIM and Quantity Takeoff Process The lifespan cost engineering of the project is aided by the cost estimation and scheduling that designers, contractors, and operators participate in a BIM-based QTO process. Software based on BIM that can extract rich information from BIM models for cost assessment includes Tekla Structures, Autodesk Revit, and Autodesk Navisworks. This reduces labor costs and time by streamlining and enhancing the precision of cost estimation. However, it takes time to manipulate QTO reports. To enable information transmission between cost estimator software and BIM software through a shared database, Industry Foundation Classes (IFC) or Application Program Interface (API) are commonly used.

QTO Process Automated BIM Framework Components

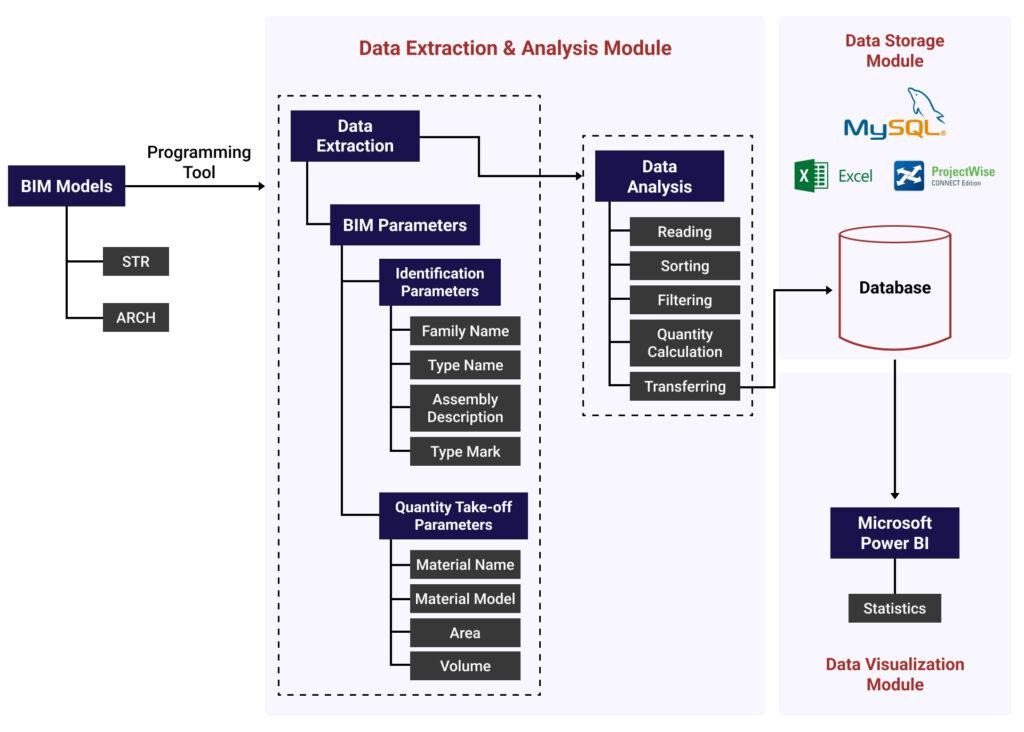

Considering various levels of quantity precision check (QPC) of BIM models, a framework has been designed to provide high accuracy in structural and architectural quantities. The framework comprises a BIM-based model, data extraction and analysis, storage, and visualization modules. It evaluates the consistency of the quantities extracted, computed, and analyzed automatically from 3D BIM models.

1. Initial BIM-based Model

The first step and part of the process is creating the BIM model, which can be done with Autodesk Revit. Utilizing BIM models, the system takes identity data features such as material, name, family, and assembly information into account and geometric aspects like volume, area, length, weight, etc., for the QTO/QPC process. Additional identification data parameters are handled by the system for inconsistency checks. The BIM models provide the structural and architectural elements necessary for the QTO procedure.

2. Automated extraction and analysis of data

The selection, filtering, sorting, and data analysis between structural elements and their parameters are automated using Dynamo, a visual programming and computational design tool. Filtering based on Work set and Phase parameter names, extracting pertinent parameters from selected concrete and steel elements, and choosing and extracting elements from structural BIM categories are all a part of this automated QTO procedure. After the data extraction and analysis from the model, the next step is storing the analyzed data.

3. Storage of the Extracted Data Analysis

The following stage involves storing data and findings from the Data Extraction and Analysis Module in an Excel database. The database includes quantities determined by the engineering team from 2D drawings, bidding quantities, and the total quantity of each category from the BIM. The figures gathered from the bidding and 2-D drawings are used for tracking and comparison, while the BIM quantities computed by the developed modules are updated automatically for the QTO process of the project.

4. Visualization of the Data

The BIM model helps in the extraction, analysis and storage of data, requires a data visualization module as the final component of the QTO process. Power BI dashboard is an example of this module that helps in the visualization and examination of the QTO findings for the various project elements such as steel, concrete, glazing and precast architectural concrete. This module allows the comparison of 2D and BIM values with bid amounts and helps track design modifications made to the quantities to help avoid overspending

Benefits of using Automated BIM QTO process

Although correct quantity takeoff necessitates that every component in a BIM model has the required information, the 5D BIM-based quantity takeoff offers a quick way to estimate quantities from architectural designs. Listed below are the benefits:

- Time and Resource Saving: Estimators and contractors can save time and resources using BIM models, which offer dependable and precise estimates of quantities and costs. This facilitates the quicker preparation and updating of QTO reports.

- Enhanced accuracy: BIM quantity takeoff, combines 3D models with all construction stakeholders, due to which accurate quantity and cost estimates during the planning stages can be calculated.

- Consistency of Data: due to the automated QTO process, the data is connected to every element of the project which provides data consistency across all phases.

Conclusion

BIM technologies facilitate automatic quantity takeoff in AEC projects and are essential for monitoring design modifications and their effect on construction costs. It can be concluded that accurate BIM models aid in the Quantity Takeoff process when they are employed in the design stage of projects, as the QTO process can improve the efficiency and accuracy of cost and quantity calculations.