Prefabricated MEP Drawings

MaRS Trans USA LLC offers MEP Pre Fabrication Drawings for prefabricated MEP components and modular construction.

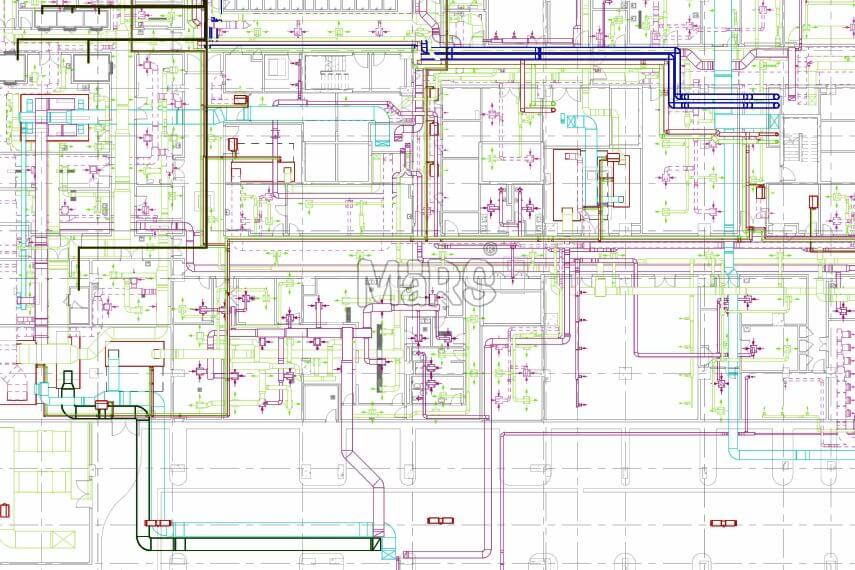

The Traditional MEP construction process involves multiple steps. It involves the installation of a myriad of MEP components from various disciplines such as Electrical, Mechanical, Plumbing, etc. This is done with the help of different specialists bringing in their expertise and skills at different stages during the project lifecycle. Thus Coordination between these teams is of extreme importance and is simultaneously extremely cumbersome and challenging. Several problems can arise due to improper MEP Coordination such as inefficient use of resources, un-explanatory delays, and an inadvertent rise in project cost. All of this can be avoided with the use of prefabrication or modular construction.

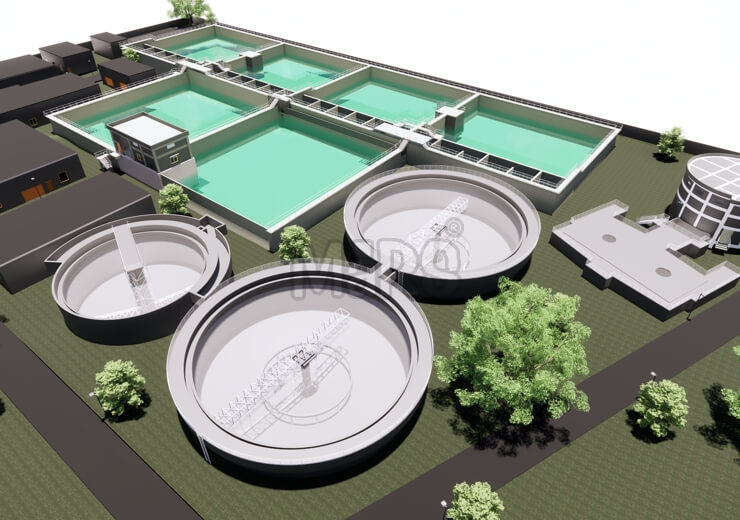

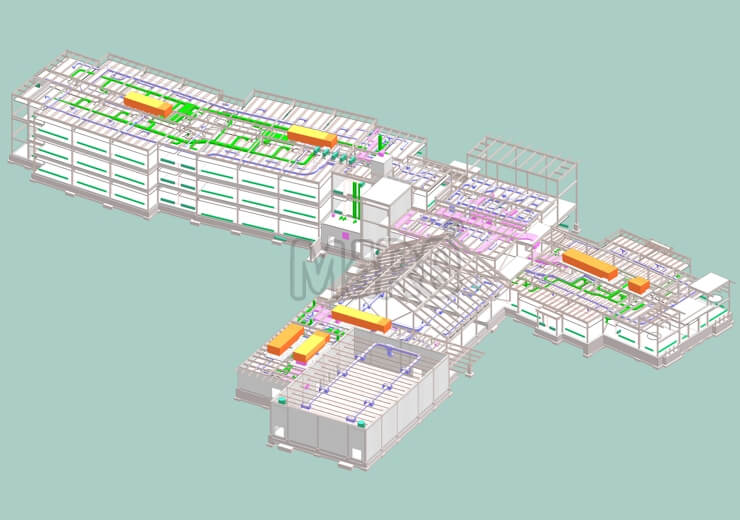

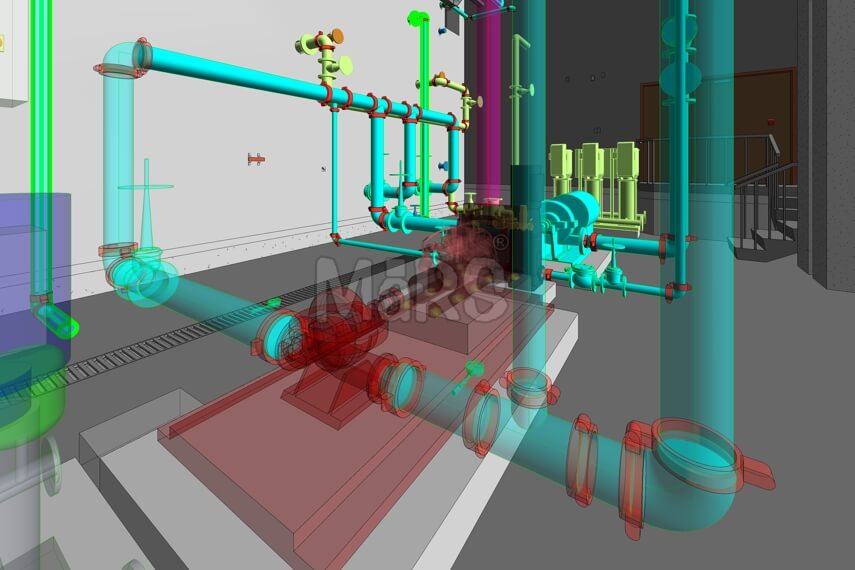

MEP pre-fabricated drawings can help integrate several MEP components and design the required modules. These modules can further be manufactured, inspected, tested, and assembled offsite and can be prepared for their installation at the allocated space at the required time.

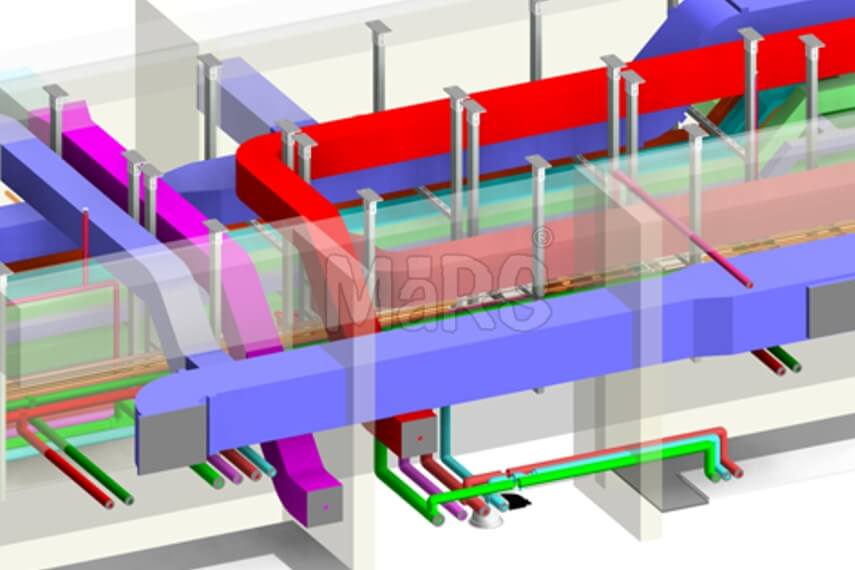

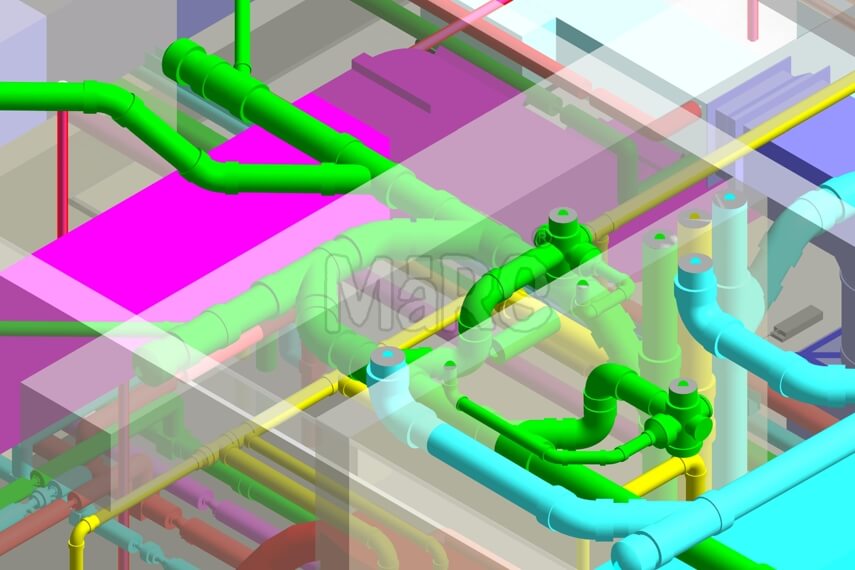

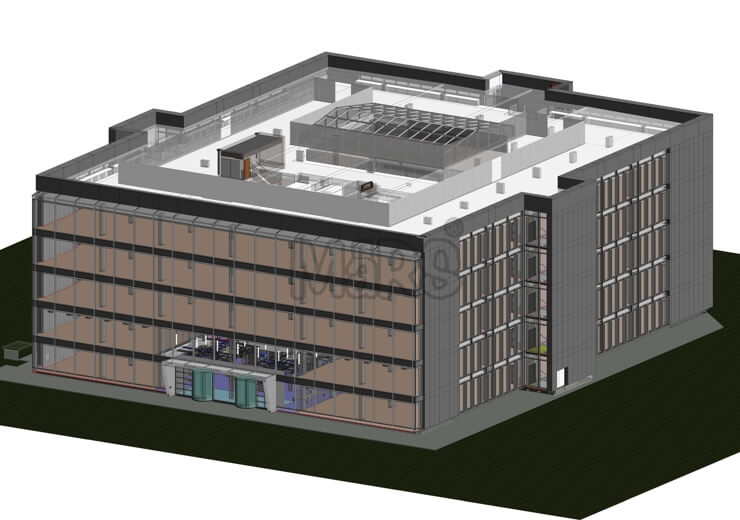

We at MaRS are more than capable of providing fully coordinated, clash-free MEP Prefabrication models. Designs and Models matching world-class engineering can be produced using tools such as AUTOCAD, Autodesk REVIT, Navisworks, and clash detection services. The information extracted from these models would be highly accurate thus ensuring a smooth and efficient production process.

We provide our Prefab MEP modeling services at any stage of the project, covering coordination, installation, Fabrication and As-Built Stage.

Our MEP Prefabrication Modelling Services include:

- Creating module maps that aim for maximum efficiency, ease of installation and the use of modularized components

- Prefabricated MEP module design, drawings and modeling services within the BIM environment

- DfMA, drafting and modeling services for independent and individual modules and elements

- 3D modular construction drawing along with detailed Bill of Quantities and schedules of equipment

- Spool drawings for efficient and timely manufacturing

These prefabricated drawings can be majorly useful for contractors and fabricators. The fabricators would be able to retrieve detailed drawings and designs for producing accurate faultless models. The contractors would be able to bank into various benefits such as faster and timely delivery of the material when required, lesser wastage of material, reduces labor costs, quality assurances, minimal disruptions and traffic at the site, easier adaptability, and a safe process for installation.