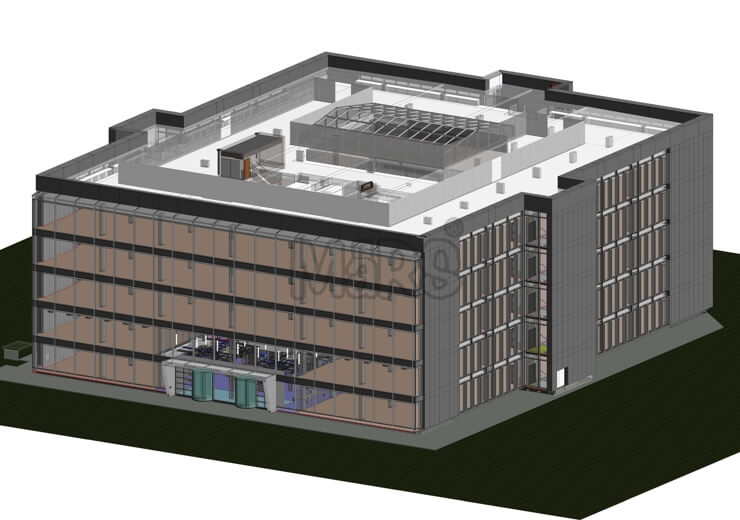

MEP Shop Drawings Services

MaRS Trans USA LLC offers a wide spectrum of MEP shop drawing services which are created with absolute excellence and precision. Our expert team excels in making high quality shop drawings for your MEP projects.

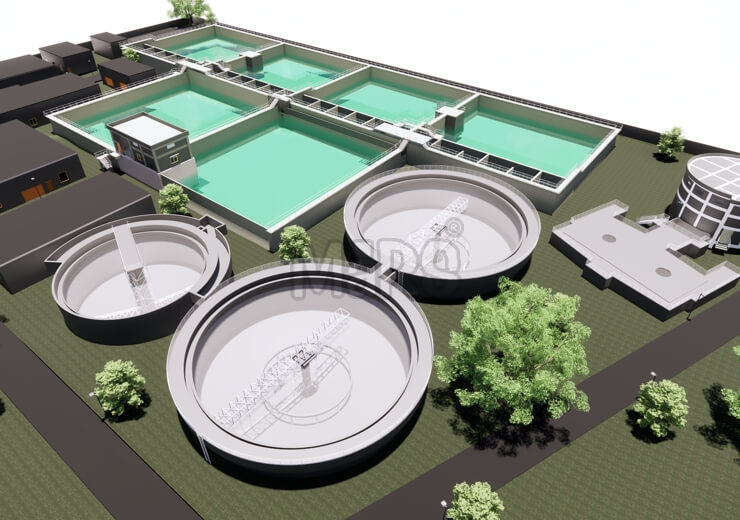

MEP is the acronym for Mechanical, Electrical and Plumbing. The various MEP element present in a project acts as a solid base for the building project. It makes sure that the minute details of the building related to heating, air conditioner and ventilation are at place and can be utilized in the right manner after the final completion of the building project. This is a complicated thing to work on and that is why professionals who have relevant experience on such things can execute the work flawlessly.

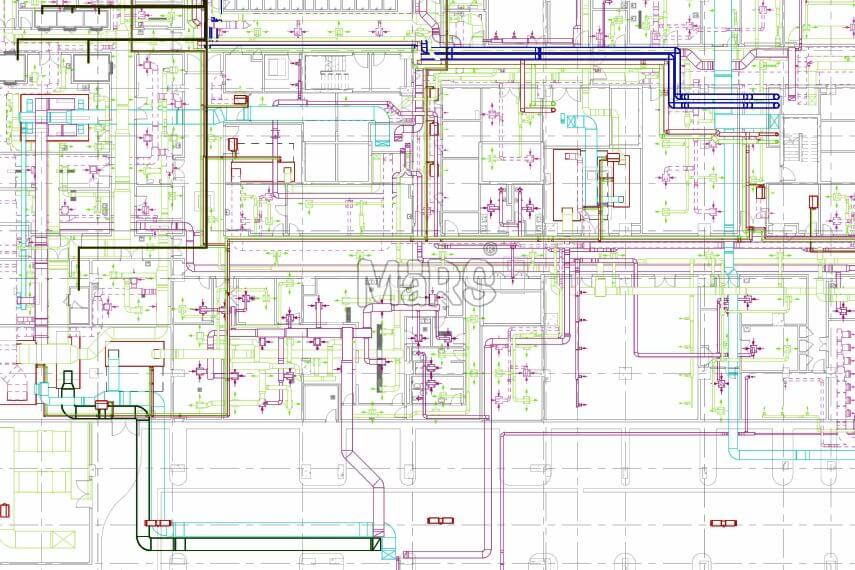

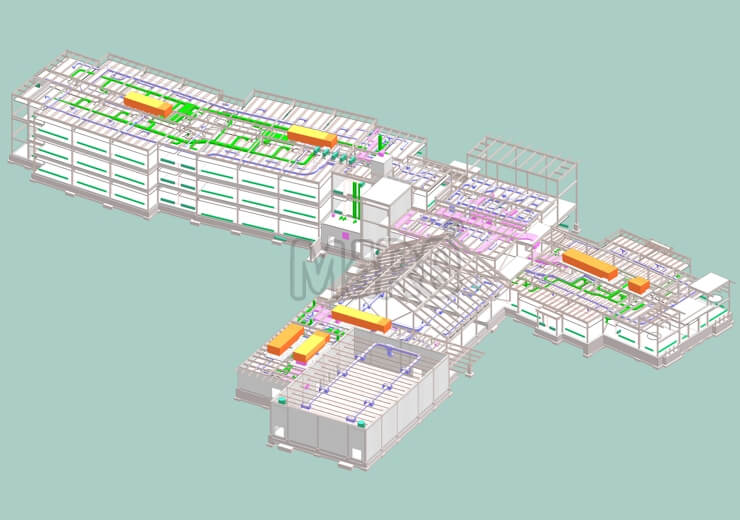

There are many things in a MEP shop drawings that completes it such as the structural aspect and the architectural aspect of the building design. Whenever required other stakeholders like the contractors, architects or engineers can give a look and find the required information through the drawings. These are basically supports the document sets that contains designing details. It also helps in bringing down the cost as well as time needed for completing the project and provides the stakeholders an effortless solution.

We at MaRS Trans USA LLC understands the importance of getting quality MEP drawings. We also know how reworks and faults can lead to expense increase of any AEC project. And that is why we are here to ensure that our BIM experts can help you decrease your cost overruns and provide you with the highest quality MEP BIM drawings possible. We create accurate MEP drawings for engineers, contractors, MEP designers and fabricators. We have a clear idea of enabling the project outcome through our well-crafted drawings.

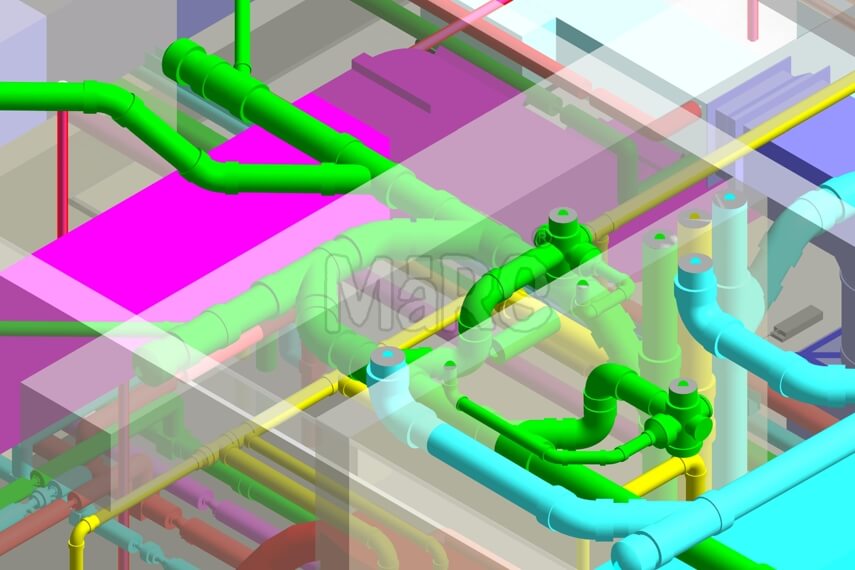

Our MEP drawings are created with maximum accuracy to enhance the level of your productivity. By getting MEP shop drawings from us you can

- Track any kind of change, addition or deviations from the original construction document.

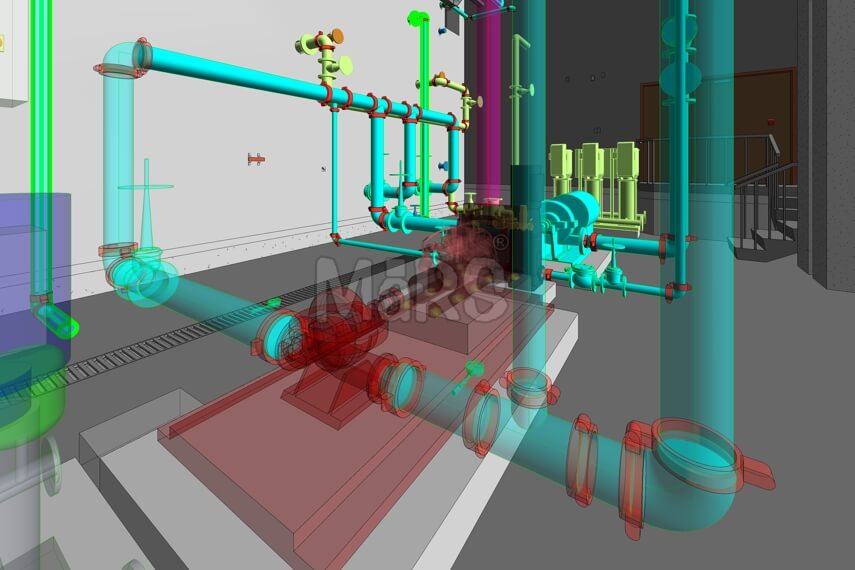

- Get a clear picture of the fabrication drawing for having better control on the coordination.

- Have the exact location of installation where the MEP systems can be put, that can decrease any expensive reruns.

- Get proper verification of the on-site components by comparing them with the MEP elements.