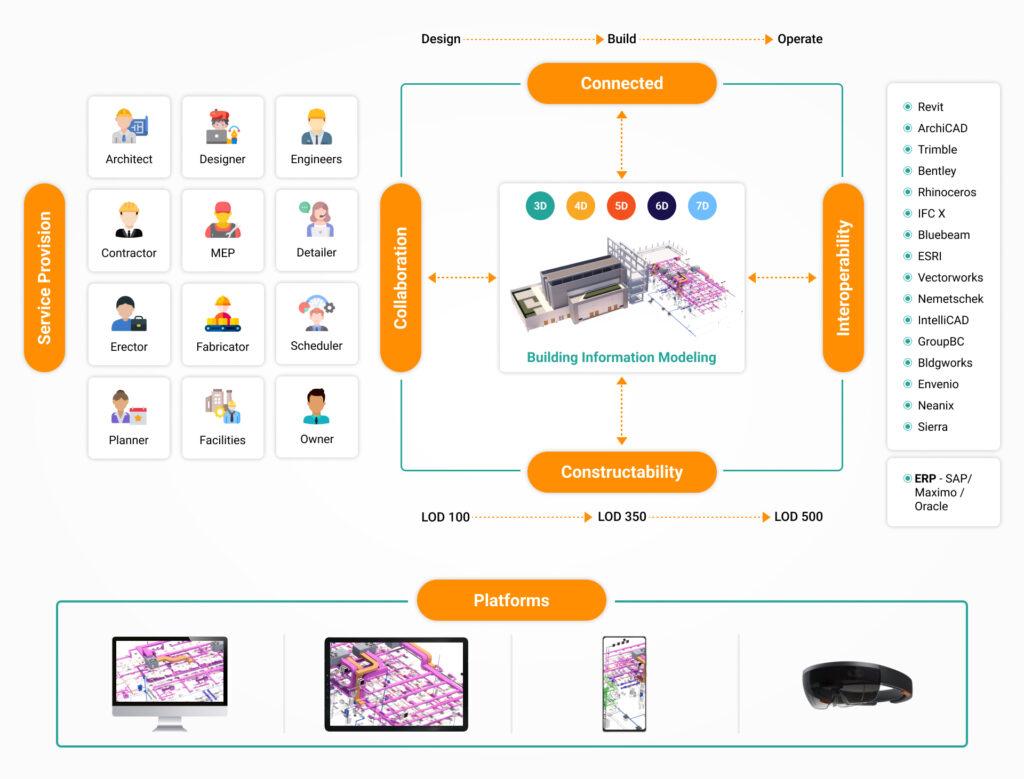

While the industry struggles to use Building Information Modeling (BIM) beyond the design and conceptual stages, its comprehension and application in medium and large-scale projects is rather high. When “data silos” are accepted, it becomes more difficult to communicate valuable information, including shared models, which can enhance accuracy and project collaboration. More precise construction and manufacturing work direction will be possible with enhanced constructible modeling.

Contractors believe BIM adds the most value during the construction phase, while a 2014 McGraw Hill study revealed that it was frequently used throughout the conceptual and engineering phases of projects.

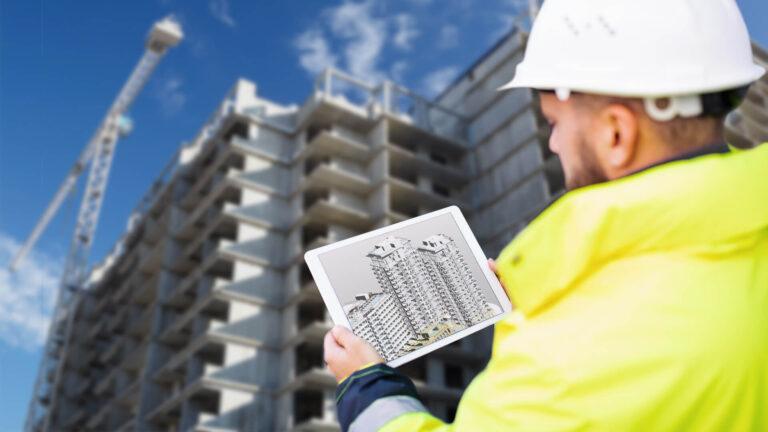

In the field, high LOD models are required for manufacture, layout, and installation, and constructible models are necessary for better coordination amongst many crafts. Using shared, constructible information for reference or sending it straight to the field for planning, fabrication, QA/QC, and earthwork is a superior strategy.

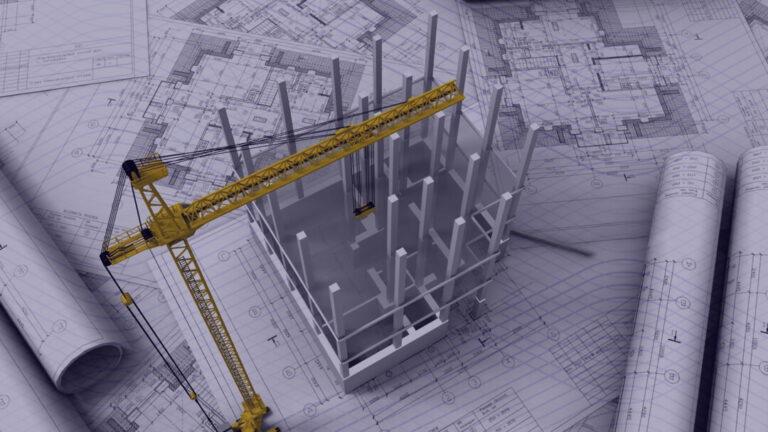

BIM Constructible Workflow

As design, project management, and engineering models are combined into one data-rich collaborative platform, BIM is evolving from a visualization tool to a constructible process. This enhances visibility, speeds up modeling, and increases predictability for trades including general contractors, architects, engineers, and specialist trades. Collaboration amongst different professions and productivity are also enhanced. A 3D constructible model that is data-rich and can be shared throughout the project is the end product, serving as a virtual twin of the actual building that is now under construction.

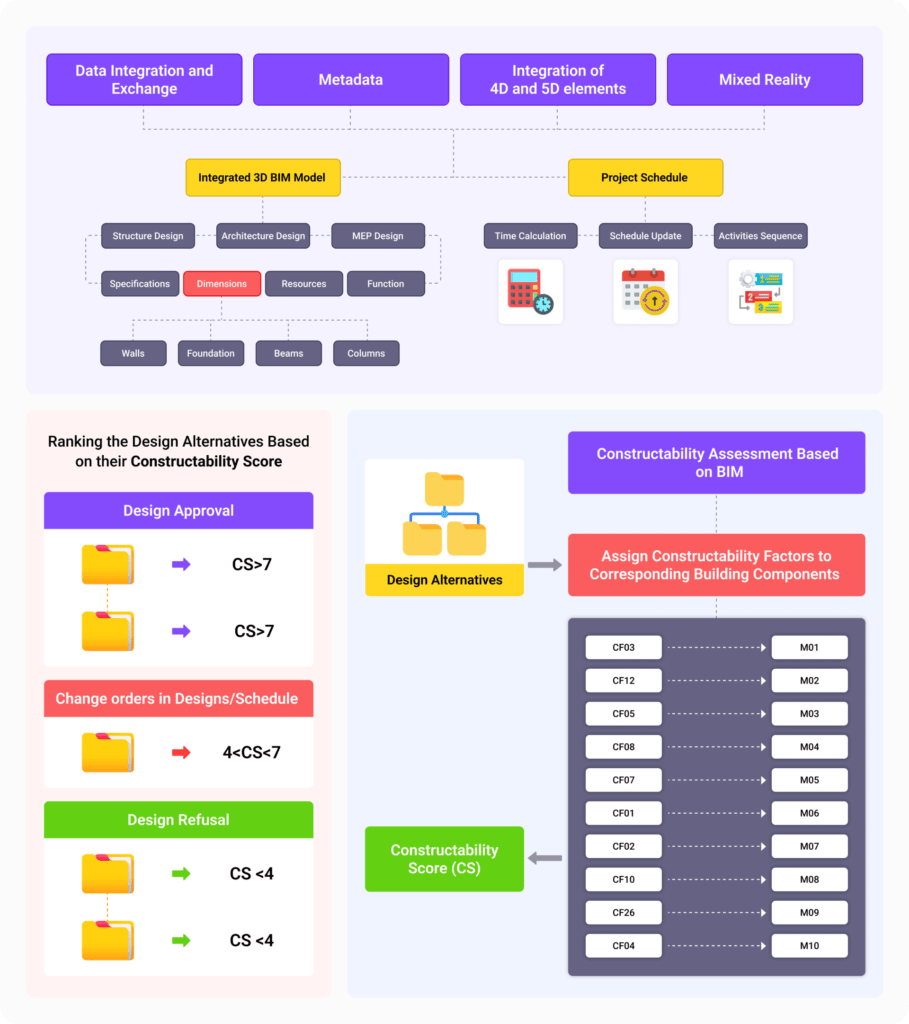

Forming the basis of the constructible BIM process are data interchange, metadata, mixed reality, and the integration of 4D and 5D elements.

Data Integration and Exchange

- Enhancing collaboration and processes, the constructible process entails the secure transmission of data across various organizations and systems. Data interoperability and validated design content are involved.

- Standards, common languages, and simplified data sharing are among the technologies that facilitate this process.

- Organizations can decrease rework, increase information accuracy, and lower overall project costs by incorporating constructible BIM workflows.

- Constructible BIM and more efficient project delivery will be pioneered by civil and building contractors who collaborate with owners to harness data and insight from design-construct workflows.

Metadata

- Constructible models can boost output, cut waste, and enhance safety since they contain important metadata that is utilized throughout the building process.

- Content-enabled models can furnish contractors with precise data to work with throughout the design phase, generating comprehensive bills of material, figuring out when to fabricate and install them, and maximizing asset performance.

- A true constructible process, including fabrication procedures directly from the model, can be driven by high-level detail models. Additionally, by using automated installation techniques to further optimize rebar placement, this data can increase installation productivity.

- Leading specialist contractors today are driving offshore fabrication and prefabrication with High LOD constructible models.

Mixed Reality

- The ability to examine 3D BIM models in the context of the physical world thanks to mixed reality technology is completely changing the construction sector.

- This technology allows to overlay of 3D BIM models on real-world locations, allowing precise virtual project site inspections.

- Enabling field crews to experience design data in context and removing the requirement for prone-to-error interpretation, increases the usefulness of constructible models.

- Members of the team can now easily spot differences between the actual constructions and the designs.

Integration of 4D and 5D elements

- Constructible processes incorporate time and schedule, production control, 5D cost estimation, and 3D models with 4D parts. By connecting design components to scheduled work, this method offers a greater understanding of a project.

- A constructible model with budget and schedules, for example, can be used by an HVAC contractor to manage daily work orders, precisely track labor tracking and as-built scan data, and connect production data to the model.

- This makes it possible to analyze labor productivity and pay subcontractors more effectively because decisions are supported by verifiable data.

Impact of Adopting Constructible BIM Workflow

Constructible BIM is useful mainly because it makes it easier to create comprehensive models for each trade and enhances the usability of construction data in the following ways:

- Data Consistency: Because constructible information is regularly contributed to the library, constructible BIM guarantees consistent data access and retrieval for estimators, detailers, and project managers.

- Accuracy of Data: Since manufacturers modify their products, custom components in models can lead to erroneous findings.

- Data Interpretation: Building information modeling that is constructible guarantees component specifications that are up-to-date, consistent, and data-rich.

Conclusion

Field personnel must have access to BIM data to use the Constructible Process and comprehend the construction components of the plan. Constructible models and workflows facilitate collaboration between field and office workers by offering comprehensive insights into component development and interaction. This benefits all parties involved. This gives all project phases the ability to identify problems early on and solve them more effectively before actual production starts.