The construction of buildings depends substantially on MEP (Mechanical, Electrical, and Plumbing) systems, which are developed collaboratively due to their significant interaction and dependency. Building information modeling (BIM) aids in creating a network between all project-related components and offers insightful early design information. As a result, conflicts in equipment location that can occur when designed individually are avoided with an integrated approach. Engineers can use the information and resolve conflicts before the start of work by coordinating MEP BIM.

BIM and MEP Design – An Integrated Approach

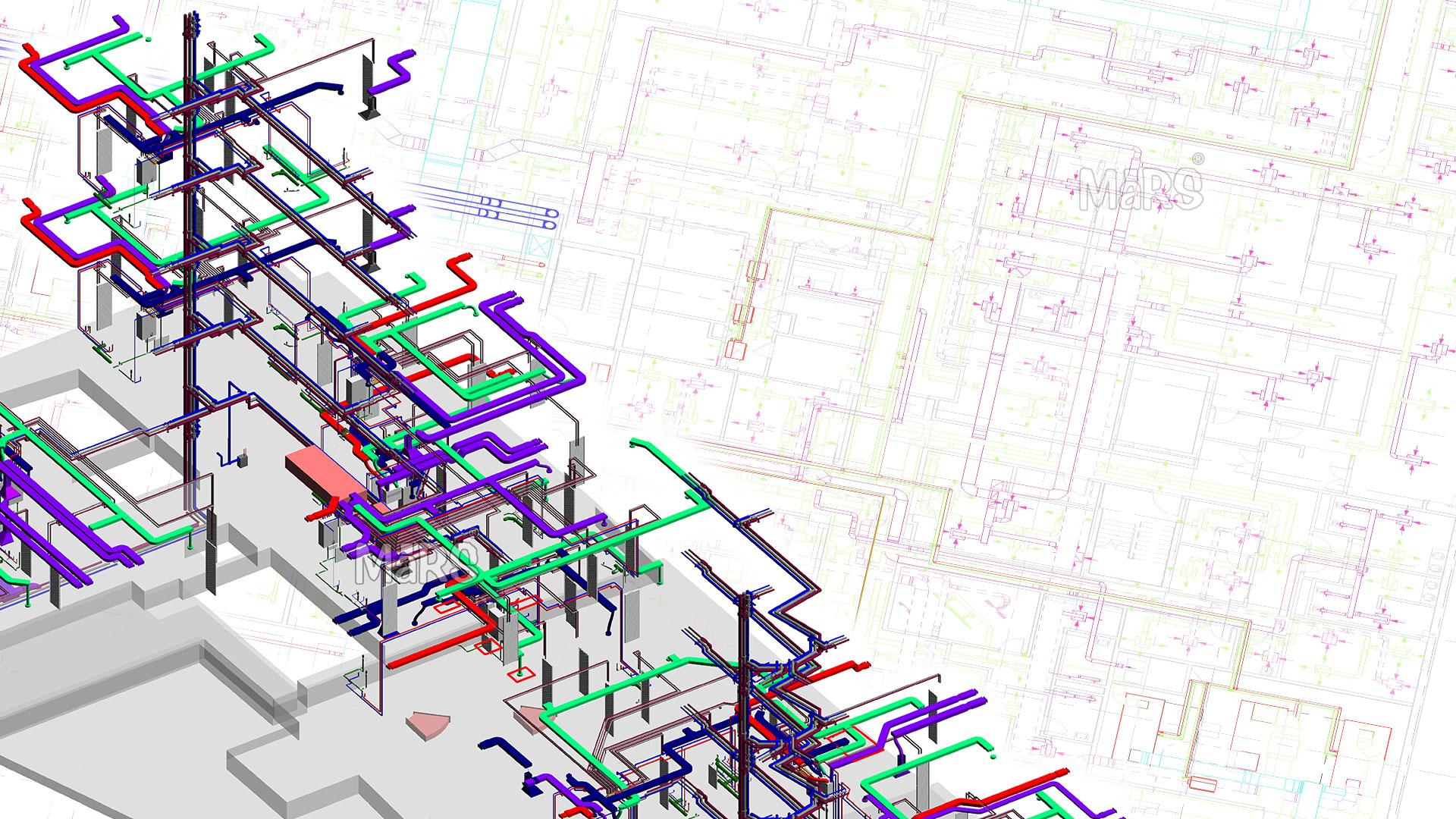

Building information modeling (BIM) in the form of MEP BIM focuses on mechanical, electrical, and plumbing systems. MEP BIM Modeling frequently includes detailed digital representations of construction projects and is integrated into Level 3 BIM models. This integration of many building components helps avoid disputes, lessens errors, and lowers project costs. The MEP design process is made simpler by using an integrated approach to building systems, which improves design outcomes.

Using the MEP BIM model, the following processes can be performed which help in simplifying the MEP Systems Design and Installation process: Creation of a 3D Model, Sizing and Computation, and Cost Projection.

Creation of a 3D Model: Using integrated libraries and customization options, BIM models parametric objects with geometric, dimensional, and performance-related information. This enables design, construction, and asset maintenance.

Sizing and Computation: Based on predetermined standards, BIM MEP software performs electrical and mechanical design calculations like cable sizing, short circuits, ESP, and fire pump head calculations.

Cost Projection: By incorporating specific prices from a pricing list with the objects and quantities in the 3D model, a BIM model helps with automatic cost estimation.

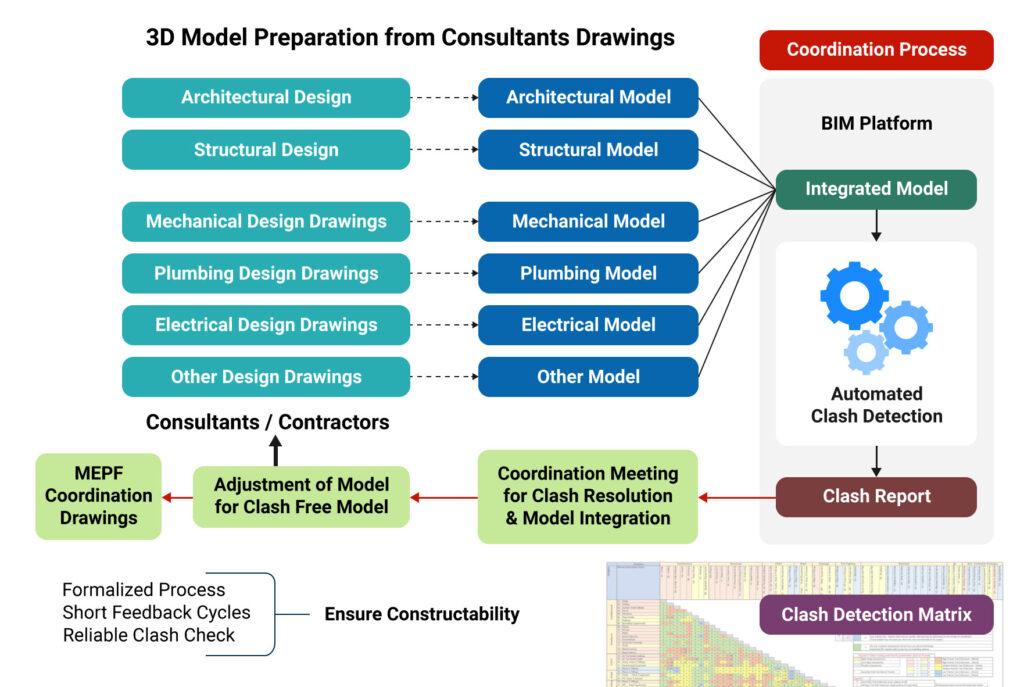

BIM MEP Coordination and Services

MEP coordination is a multidisciplinary process that integrates MEP designs into architectural and structural plans for buildings. These active systems, which can cost up to 60% of a project, according to Korman and Huey-King 2013, are essential parts of a building. The constructability assessment process includes a crucial activity called MEP coordination that calls for expertise in design, building, operations, and maintenance.

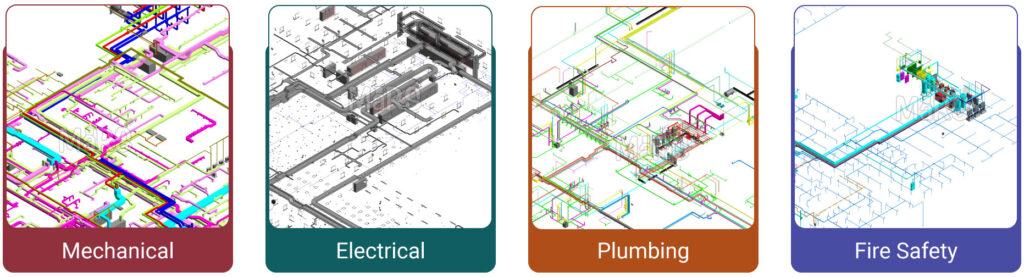

BIM coordination is used by MEP services, such as electrical, plumbing, and mechanical services, to guarantee precise and effective design and construction.

- Mechanical BIM: For the creation and use of computable data on structure mechanical design, efficient workflow, scheduling, and geometry assurance, mechanical BIM services are essential. In addition to shop, fabrication, and equipment specifications, they comprise numerous drawings, details, and models for HVAC components.

- Electrical BIM: Structure components are displayed on electrical frames, which also provide installation locations and angles for proper electrical design. Drawings for electrical parts, such as site plans, line diagrams, schematics, power and lighting designs, and solar panel detailing, are included in electrical modeling.

- Plumbing BIM: For effective planning, administration, design, and construction of plumbing lines in buildings, plumbing BIM Services offer precise 3D models. They minimize waste and on-site alterations by specifying the shape, size, and basic specifications of plumbing pieces and ensuring precise clash resolution.

BIM MEP modeling unifies various disciplines into a solitary 3D model, giving detailed perspectives and enhancing design outcomes. It emphasizes the effects of design decisions and creates a comprehensive understanding of the building system. The model can be exported in the open data format Industry Foundation Classes (IFC), which guarantees professional data exchange without any data loss or distortion.

Advantages of using BIM for MEP Design

MEP contractors can gain from using BIM during the design phase by accomplishing the following:

- Early Clash Detection: Conflicting locations within a building structure can be found using clash detection features incorporated into BIM modelling software like Revit. Resolution of conflicts at the design phase, according to the Building and Construction Authority, helps avoid serious repercussions later in the project.

- Reduced Change orders: Change orders may result in project cost overruns and delays. BIM assists in identifying these changes at the design stage, which lowers material and labor costs. Engineers can use it as a potent project-tracking tool to keep track of progress and spot inconsistencies.

- Increased Work Efficiency and Higher Quality Projects: BIM assists professionals and stakeholders in producing efficient high-quality designs while staying within budget by resolving conflicts, creating accurate site measurements, and streamlining communication. MEP BIM coordination services offer versatility, smoother modifications, cost savings, and scalability.

- Improved Project Visualization: By providing a 3D model for every angle of the project, BIM technology streamlines project visualization, enables MEP specialists to better comprehend structure layouts and support design efforts, and streamlines redesign by making it simple to edit models.

Conclusion

AEC experts, including MEP engineers, can work together using the model-based BIM methodology to comprehend project integration. The MEP Design and Installation process is made simpler for successful projects because it defines design elements, develops relationships, and decides how they function.