In the construction industry, steel detailing is a critical step that converts architectural and technical concepts into particular designs for steel fabricators. It entails producing comprehensive specifications, drawings, and instructions for the fabrication, assemblage, and erection of steel components. To guarantee correct depiction and appropriate integration, structural steel detailers collaborate closely with architects, engineers, and contractors.

The two primary types of drawings that structural steel detailers create are Erection drawings and Shop drawings.

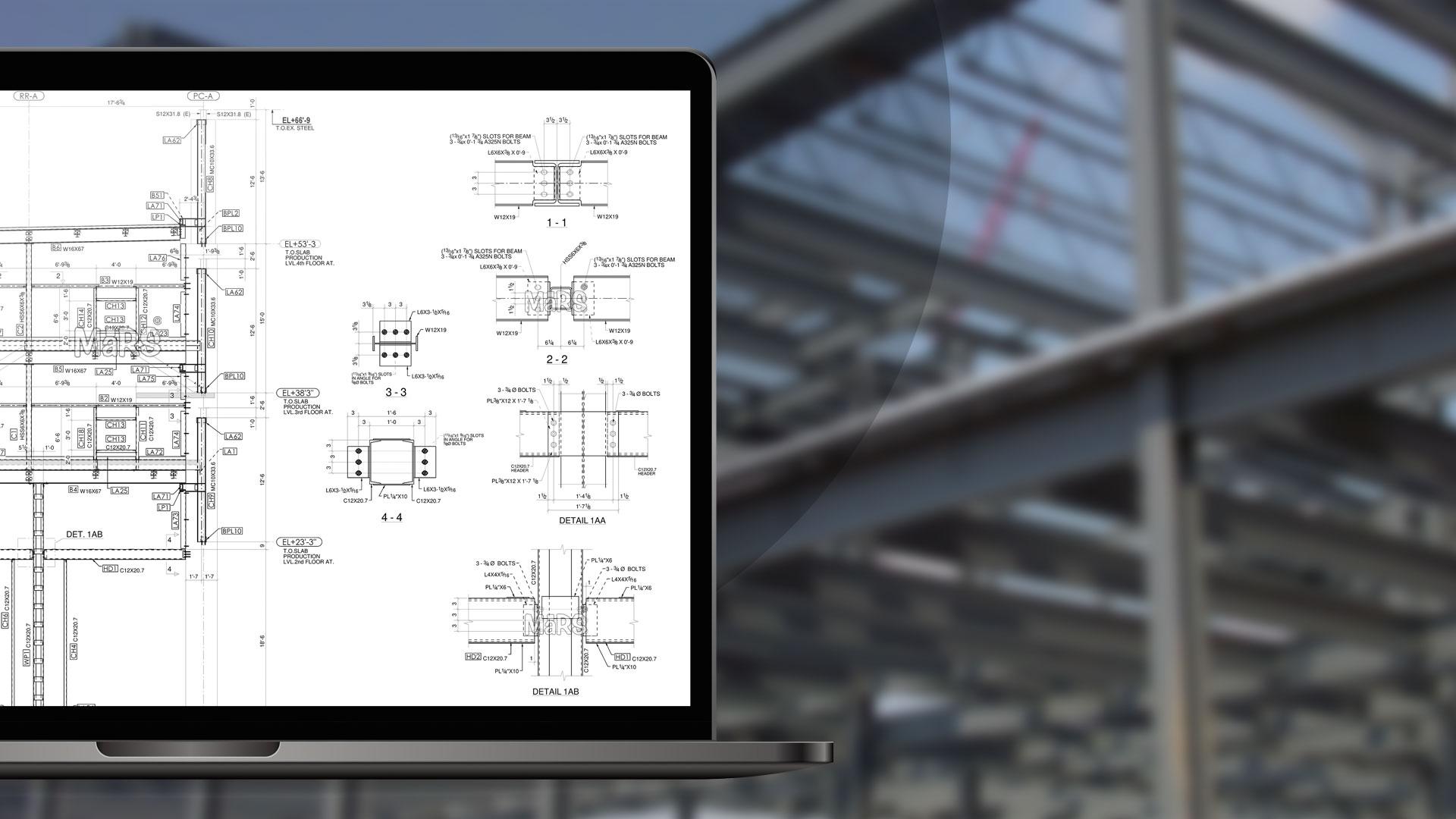

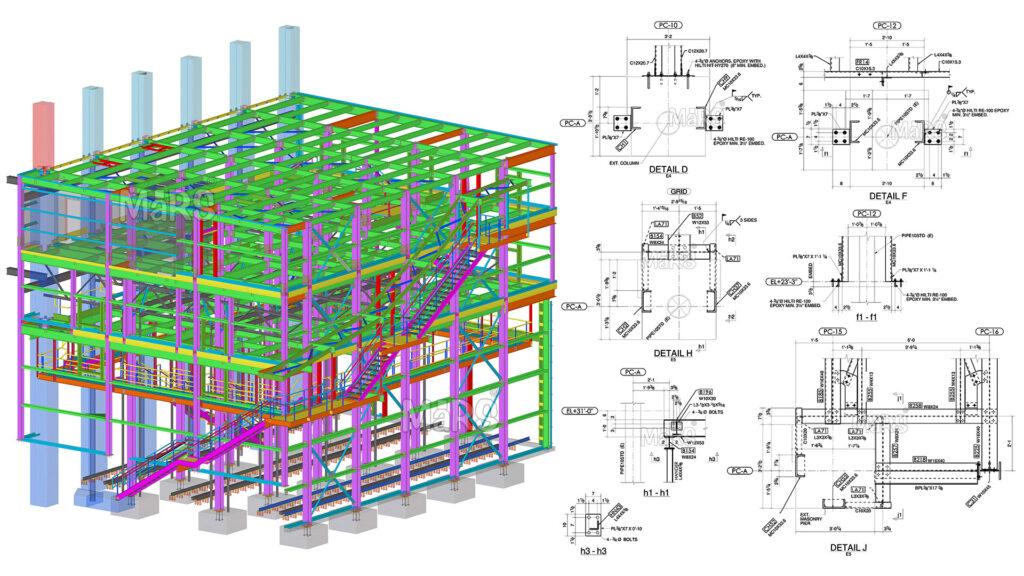

Erection drawings, which detail assembly and installation processes, schematics, design calculations, and procedure manuals, are crucial documents for steel erectors on construction sites. They contain dimension drawings, requirements, and necessary on-site tasks like anchoring, welding, and bolting, but they lack specifics regarding the production of individual steel members.

Shop drawings, which provide sections, dimensions, details, welding information, and fabrication standards, are essential in the steel fabrication industry. Each steel component, including connectors, columns, beams, and trusses, is described in detail. Understanding dimensions, material type, installation process, puncture placements, and member connection details is made easier by accurate shop drawings.

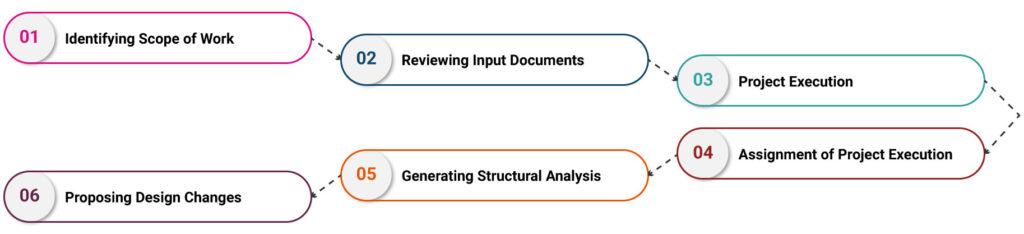

Process of Structural Steel Detailing

The fabrication, assembly, and installation of steel structures are all controlled by the accurate designs and specifications that are created throughout the steel detailing process.

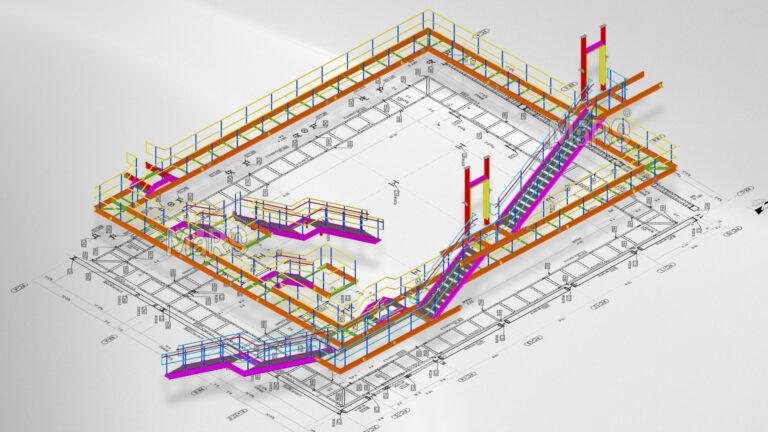

- Creation of Design Drawings: Using specialized software, the detailer produces precise 2D and 3D drawings that represent steel parts including columns, beams, and braces. Along with dimensions, floor levels, and material alternatives, the engineer specifies sizes, orientations, and connections.

- Materials and Budget Assessment: The contractor, fabricator, or erector uses the design drawing to evaluate the project’s volume, material needs, time-frame, available resources, and probable trouble spots to provide an accurate cost estimate.

- Creation of Shop Drawings: Fabricators create shop drawings to provide complete production instructions for steel components, including dimensions, material needs, connection details, welding details, and assembly instructions. Before construction, they also provide an erection mark.

- Creation of General Arrangement Drawings (GAD): A GA drawing, also known as a marking plan or marking elevation, is made using specialized modeling software to show where fabricated components should be placed on the job site and how they link to other members.

- Coordination with Architects, Engineers and Contractors: Architectural, engineering, and construction professionals work together with structural steel detailers to verify that steel components adhere to project design and structural requirements, resolving design issues, and assuring smooth construction.

Benefits of the Steel Detailing

Construction projects demand close attention to structural steel detailing. It helps with:

- Precise Fabrication details: To ensure appropriate manufacture, minimize errors, and enhance the overall quality of steel components, steel fabrication drawings give exact information on dimensions, connections, and specifications.

- Streamlined Assembly Process: For efficient on-site assembly, time savings, and minimal construction disturbances, structural steel detailing offers assembly instructions and sequencing schedules.

- Structural Safety: To maintain structural integrity and safety, steel constructions need to be connected and detailed precisely, defining key locations, load-bearing sections, and required reinforcements.

- Early Clash Detection: Design clashes between steel components and other building features can be detected via structural steel detailing using advanced BIM modeling and clash detection techniques.

Outsourcing Structural Steel Detailing

Advanced CAD software, BIM platforms, and specialized tools are needed for structural steel detailing; these technologies frequently call for investment and licenses. Businesses should use professional service providers to outsource functions to maximize technology. This enables access to the most recent tools and the knowledge of seasoned experts in the field of drafting structural steel.

The following benefits can be reaped by outsourcing steel detailing services to MaRS Trans USA:

Cost and Time Savings: By outsourcing, the clients can benefit from professionals who have expertise, cutting the cost of software purchases and boosting project effectiveness. MaRS Trans USA leverages modern software tools and processes to increase turnaround times while upholding high standards for quality.

Assured Quality: MaRS Trans USA ensures compliance with industry standards, high-quality and accurate steel details, and project requirements through knowledge and attention to detail.

Efficient Collaboration: To maintain efficient collaboration and communication, MaRS Trans USA adheres to procedures, working closely with clients to understand project needs, offer regular updates, and quickly address any queries or issues.

Conclusion

To use steel components in construction and create erection and shop drawings, structural steel detailing is essential. The use of CAD improves accuracy and precision. Structure steel detailing is a critical instrument in launching building projects since it connects specialists like engineers, architects, contractors, and fabricators.