Both the adoption of BIM and the creation of BIM schematics for existing structures are becoming increasingly essential in the AEC industry. By using the Scan to BIM procedure these schematics may be created precisely.

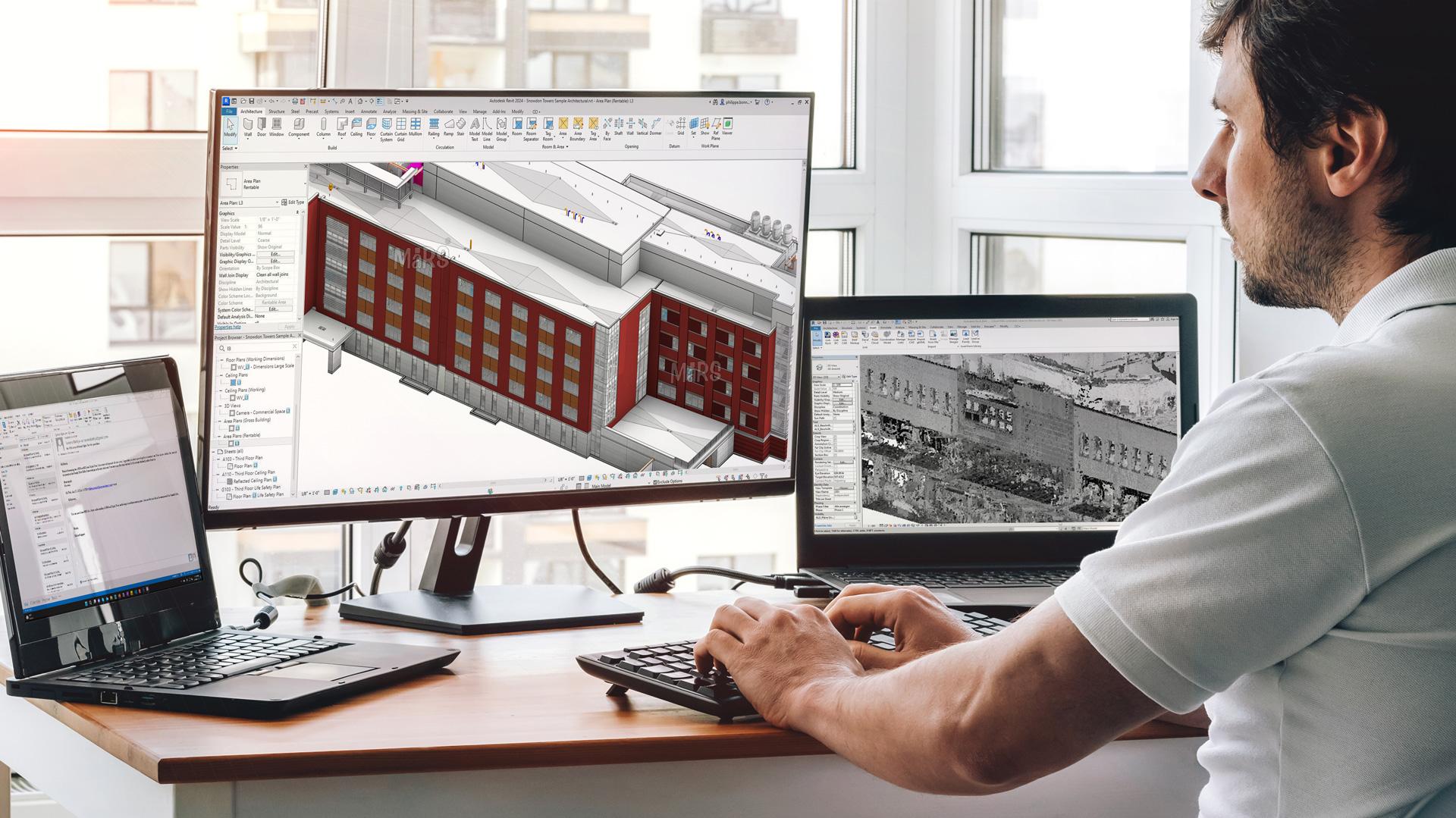

Scan-to-BIM is the process of using scan data to create an accurate as-built 3D model of a real-world location or site.

The Scan-to-BIM process provides a critical foundation for design teams employing 3D BIM models to develop their thoughts and manage, coordinate, and exchange all project information. The surveyors, owners, architects, engineers, and general contractors in the AEC sector apply laser scans to BIM best practices for their repair and refurbishment projects as explained by Gustavo Rocha in his research paper “A Survey of Scan-to-BIM Practices in the AEC Industry – A Quantitative Analysis”.

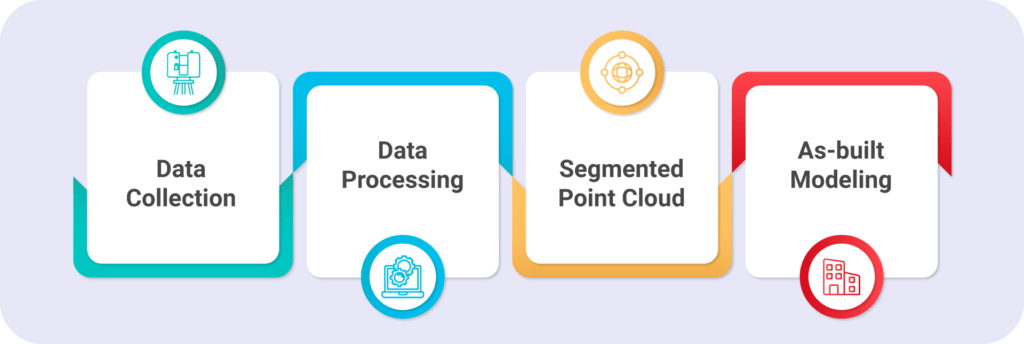

Stages of the Scan to BIM workflow process

- On-site data collection using a 3D laser scanning device

- Use a software program that calibrates it to import the raw scan data.

- The digitization and creation of a BIM model using point cloud data obtained from laser scans.

We’ll analyze further each of the aforementioned procedures, as well as the benefits Scan to BIM, offers to those working in the AEC industry in the sections that follow.

Need for 3D Laser Scans

To provide immersive visualizations of 3D data in structures, new developments, and demolition projects, scan-to-BIM technology combines point cloud data, image data, and terrestrial tripod-based laser scanners. This technology makes it possible to visualize interior rooms, exterior facades, and difficult-to-reach mechanical and electrical equipment with accuracy and life-likeness. Scan-to-BIM is revolutionizing the building industry thanks to its wide acceptance and fast scanning speeds.

Scan to BIM Workflow process

On-site Data Collection using a 3D Laser Scanning Device

The desired model’s level of detail must be identified before scanning to BIM to increase the accuracy of the as-built BIM for the intended use. Key parameters such as scan density and scan area need to be filled in the scanner. High-speed rotation of a laser inside the scanner housing records digital representations of the spaces.

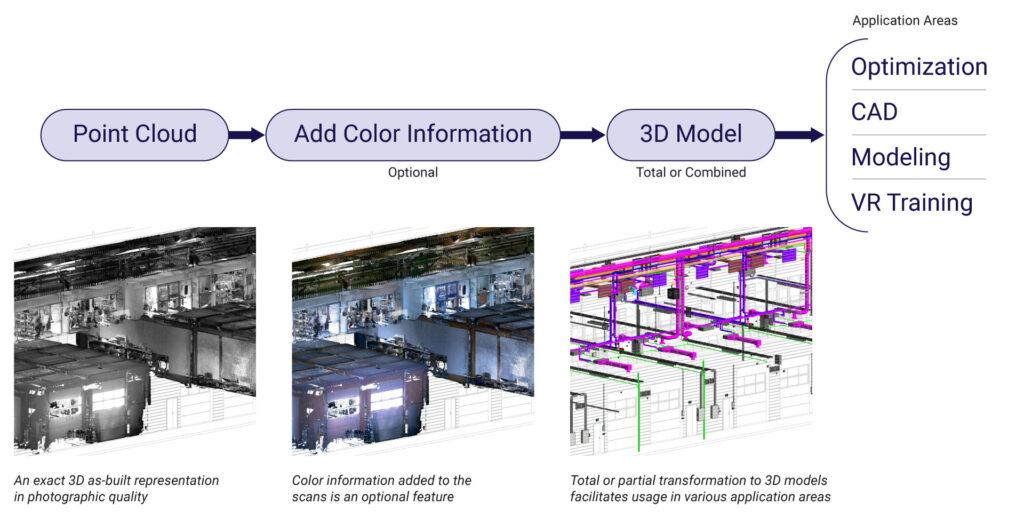

The position of each object or material struck by the invisible laser beam is saved as a “point” in the scanner’s user interface. This information, also referred to as a “point cloud“ creates an extremely precise three-dimensional computer image of the area or place being scanned.

Importing the Point Cloud Data

A USB drive makes it easier to share the raw scan data from a scanner. Before sharing the data with others or importing it into design authoring programs or a common data environment, open data in a software program to calibrate it. By the use of many viewing points in point cloud scans, BIM modelers accurately represent building systems by extracting their physical and functional characteristics.

Converting the Point Cloud Data to a 3D Model

The point cloud data can be imported into a modeling program after registration, allowing for the production of constructible model content. This information shows a building’s on-site conditions, which help with remodeling, redesigning, and renovating building spaces. After scanning to BIM, the needed As-built model is produced, replete with the relevant building system data.

Digital representation of a structure or site in real-time makes it possible to scope out work, provide precise design recommendations, and monitor progress. This effective tool improves asset management by giving a comprehensive view of the asset’s value that is accessible right now.

Advantages of using Scan to BIM Technology

- Quality assurance: By enabling you to compare project progress to planning at every level, scan-to-BIM offers quality assurance. Inspections can be conducted more frequently off-site than on-site, minimizing the requirement for travel without compromising the assessment’s quality.

- Reduced errors: Errors will be reduced because of the process’s high level of accuracy while planning modifications or expansions to buildings. Accurate floor plans in a contemporary, uniform format are now easier to obtain.

- Time and Cost Savings: The installation and assembly procedure can be simulated in a virtual environment using scan-to-BIM. This will reveal any potential clashes, which are problems or difficulties that may arise before installation, saving both time and money.

- Common Data Environment: Transparency, improved communication, and encouragement of collaboration are made possible with scan to BIM.

- Sustainability and performance analysis: It helps with building performance analysis so that it is easier to evaluate and improve a building’s efficiency concerning energy use, accessibility, and structural dependability.

Conclusion

By using 3D laser scanning equipment, BIM technology records site characteristics and generates digital representations. By lowering entrance barriers and facilitating cooperation across all project levels, this critical step in the BIM process helps AEC professionals. Scan-to-BIM improves efficiency and collaboration among stakeholders by saving time, and money, and providing a platform for real-time adjustments.