Building Information Models, which facilitate effective communication and improve understanding among trades, is a vital element in design processes. By giving precise and useful information on buildings or projects, they have revolutionized construction projects. The Level of Detailing or Development (LOD) Specification, which enhances communication regarding element qualities in models, is a crucial component of BIM. The function of the LOD Specification in BIM, the value of good data quality, and its relationship to the building lifecycle in construction projects are all discussed in this article.

Concept of LOD in BIM Used in Construction Projects

BIMs, which are used throughout multiple project life cycles, can be created with the help of the “LOD Specification” by AEC specialists. AEC professionals may successfully document and specify BIM information using the LOD, a collection of specifications that defines development stages and promotes clear communication between architects, engineers, and other experts for quicker implementation. The American Institute of Architects (AIA) published the Level of Development guideline in 2008, establishes five development levels for detailing levels in a BIM model.

The LOD specification is broken down into six levels, with LOD 100 models being the simplest and least detailed and LOD 500 models being the most thoroughly detailed, depending on the type of building system and the use of BIM.

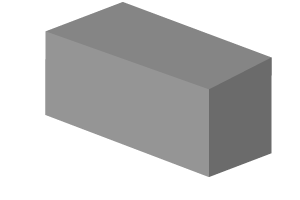

LOD 100 – Conceptual

What’s Included Basic shapes and symbols, approximate dimensions, no material or performance data

Use in Pre-design, feasibility analysis, spatial planning

The conceptual design stage is the main focus of LOD 100, the initial step in the BIM process. It offers fundamental spatial representation and massing, as well as generalized geometric shapes and a broad overview of the project’s conception.

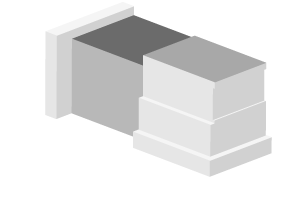

LOD 200 – Schematic Design

What’s Included Refined shapes, approximate quantities, size, and location, basic material types and properties, no detailed connections or assemblies

Use in Scheme development, cost estimations, building visualization

LOD 200 improves the original design by adding additional information to the BIM model, enhancing spatial representation, introducing particular building components and assemblies, and supplying generalized numbers and sizes for a more thorough understanding of the project’s layout and structure.

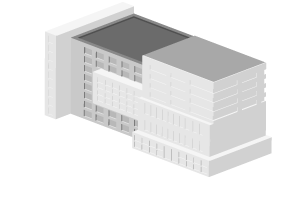

LOD 300 – Design Development

What’s Included Precise element geometry, accurate dimensions and relationships, specific material types and performance data, simple connections and assemblies

Use in Construction documentation and detailing, schedule and cost control, coordination with other disciplines

The focus of LOD 300 is on the detailed design phase, which includes accurate measurements, relationships between components, detailed quantities, and sizes, as well as the addition of preliminary fabrication and construction information for better planning and coordination of construction activities.

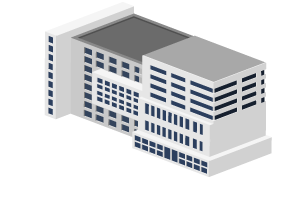

LOD 350 – Construction Documentation

What’s Included Detailed geometry with precise connections and assemblies, full material specifications and performance data, fabrication and installation information

Use in Shop drawings and fabrication, coordination of construction sequencing, clash detection and resolution

The communication between systems and elements of a building is described in LOD 350. Model elements’ quantities, sizes, forms, positions, and orientations are all described graphically and in writing. The model acts as a source of thorough data for building documentation. It includes comments and construction-level details to assist construction teams in finishing projects.

LOD 400 – Fabrication & Assembly

What’s Included Elements include manufacturing tolerances and fabrication details, precise component properties for accurate cost estimation, detailed fabrication drawings and schedules

Use in Component prefabrication and assembly, site logistics and sequencing, cost and schedule monitoring

LOD 400 uses a BIM model for fabrication and assembly, giving manufacturers and contractors exact geometry and comprehensive information. During the production and assembly phases, the model generates shop drawings and fabrication data that give fabricators and installers thorough instructions.

LOD 500 – As-built

What’s Included Models reflect the actual constructed building, full operational and maintenance data for facility management, integration with facility management systems

Use in Facility management and asset tracking, building performance analysis and optimization, maintenance scheduling and budgeting

The BIM process ends with LOD 500, which captures as-built conditions and makes facility management easier. For ongoing operations, maintenance, and renovations, it can be integrated with facility management systems, properly displays construction, and contains information on operations and maintenance.

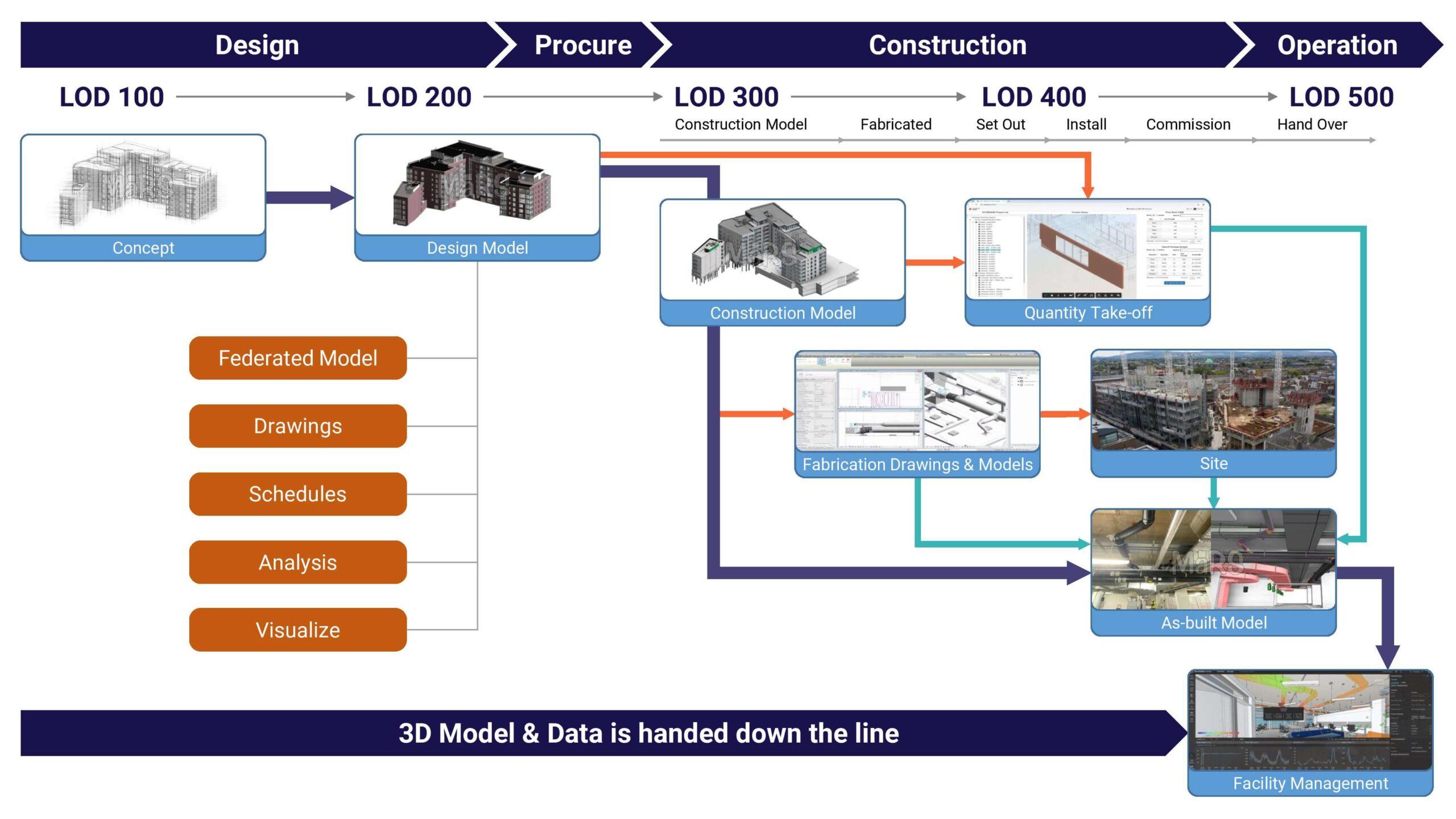

BIM Workflow with LOD

The use of LOD depends on customer requirements and needs to be decided early on in a project. The project execution plan (PEP), which should be stipulated as a contract requirement, precisely outlines the project’s objectives and procedures and thus helps in deciding the extent of LOD. The illustration below demonstrates where in the BIM workflow process each LOD can be used.

Importance of LOD

Importance of LOD

- Accuracy of Information: The LOD Specification guarantees that project teams at various phases agree on detail and accuracy, preventing misunderstandings and boosting productivity. It also improves the precision and quality of BIM models by offering precise instructions during each stage of development.

- Cost Reduction and accelerated project timelines: By giving accurate information at every stage, eliminating time-consuming adjustments during construction, and identifying design concerns early on, enabling for efficient changes and decreasing rework risks, BIM LOD lowers costs and accelerates project schedules.

- Structured and Organized Data: For data-driven construction projects to be successful, access to structured data is essential. Information overload results from difficulties organizing and structuring the massive volume of data produced by the building industry. Data collection and connection can be automated using a platform and an API.

The appropriate LOD level depends on the specific project requirements and stage. Choosing the right LOD can optimize workflow, minimize errors, and improve overall project outcomes.