Building information modeling (BIM) is a technique that produces a 3D data set for design and construction experts. This allows for the creation of precise virtual models with exact geometry and data for purchase, manufacturing, and on-site installation. BIM can help modular buildings, which are composed of parts fabricated in factories and put together on-site, coordinate, document, and fabricate MEP systems, overcoming problems in modular structures. By identifying conflicts before construction, this strategy also enables significant time and money savings. There are prospects for modular construction when all disciplines are integrated throughout the design phase.

The Elm Street Hotel and Apartments in Connecticut is a case study of successful BIM integration for modular construction; the article will proceed to discuss how MaRS Trans USA was able to succeed in doing so in this project and what services were provided by the company to ensure this integration.

Project Details and Scope of Work

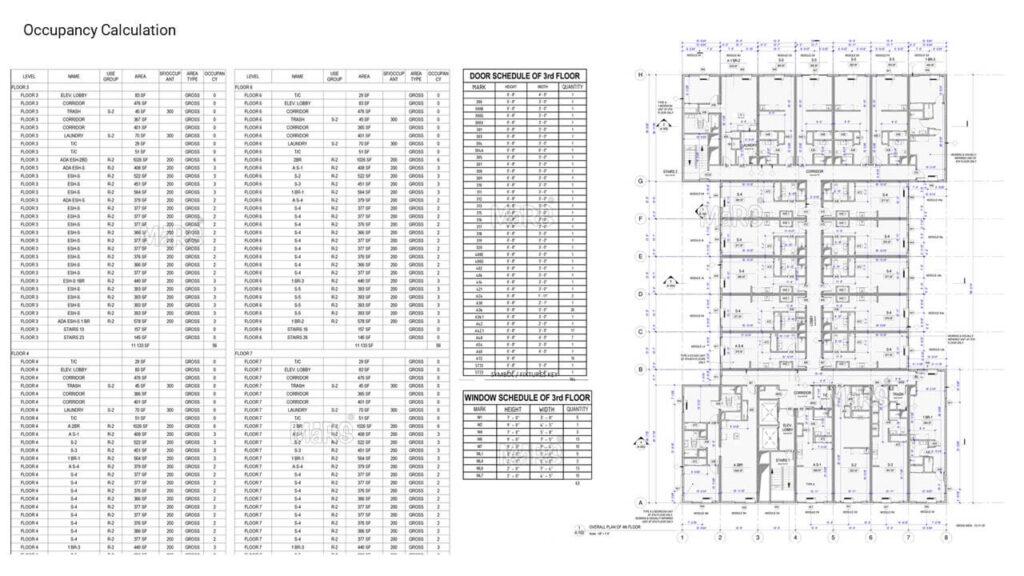

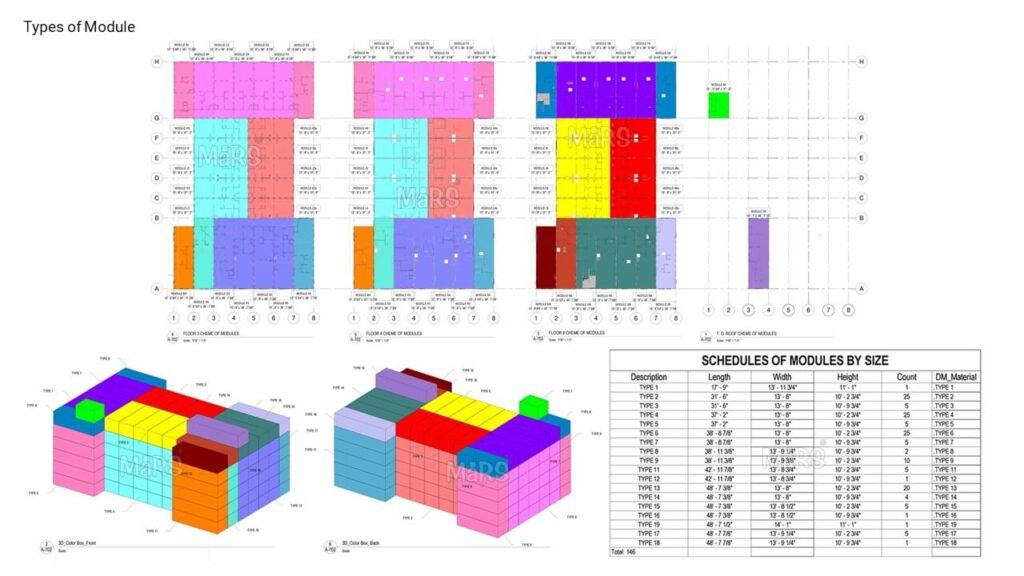

The Elm Street project is a modular construction venture comprising apartments and hotels in Connecticut developed using BIM technology. MaRS Trans USA has undertaken the BIM integration for this project, and the work scope includes all stages from conception to design development. The company offered the following services: occupancy calculations, a schedule of modules by size, layouts of the structural framing, steel detailing, connection detailing, MEP services, fire protection services, and the successful integration and coordination of all of those above.

Design and Documentation using BIM Tools

The Elm Street project has utilized architectural BIM tools from the planning stages through the design development and services coordination phases. This case study will demonstrate how several programs may be used to produce a comprehensive BIM modular model that can be used during the building’s design, construction, and operational phases.

Architectural Design

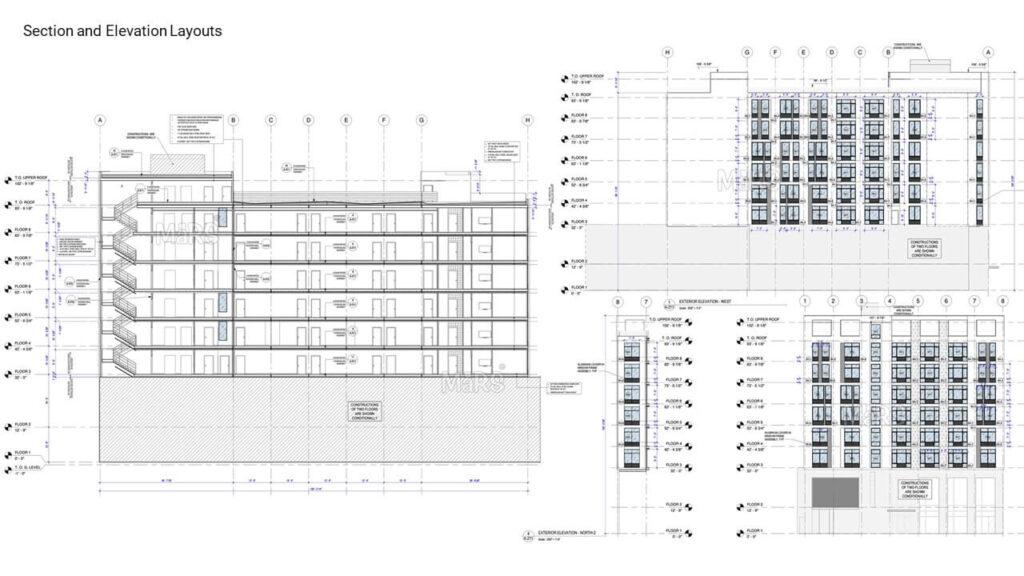

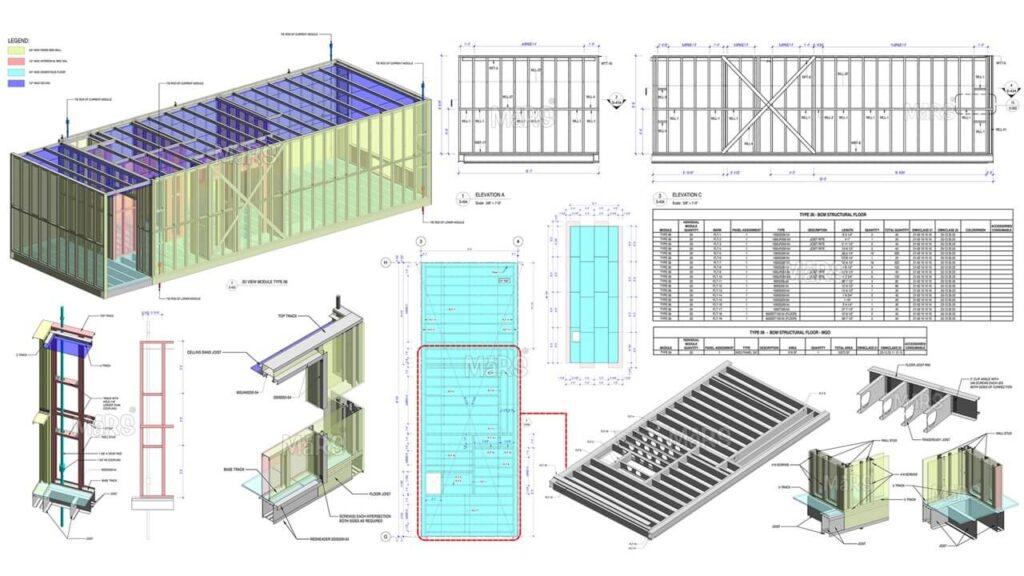

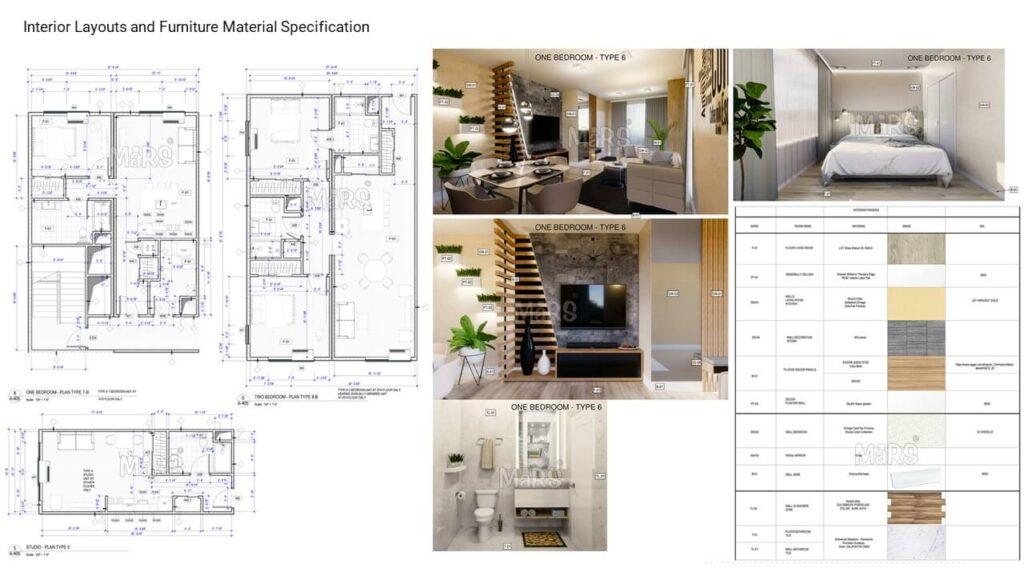

For precise documentation, a data-driven 3D modular architectural model was produced using Autodesk Revit. The interior layout along with material specifications, section and elevation layouts, views of the intended modules, and operations of MEP elements were all incorporated in the modular BIM model, which aided in the procurement, fabrication, and on-site assembling processes. The project’s key stakeholders were able to collaborate effectively during the design, construction, and operational phases because of this BIM model.

Structural Detailing Services

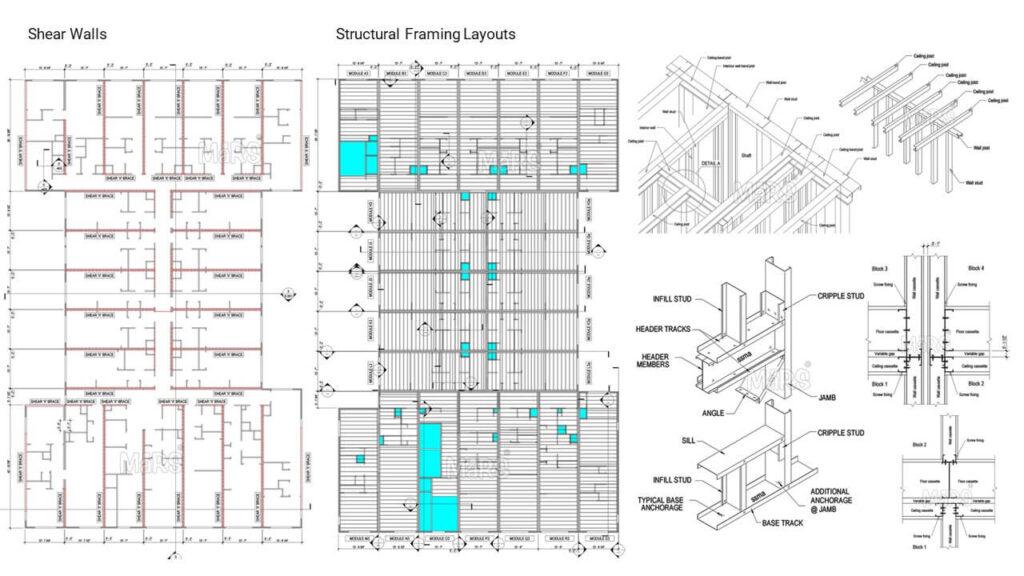

Both analytical and physical representations of the building model were produced by BIM using Revit and other interoperable software, providing crucial information for exterior evaluation. Collaboration between BIM and structural analysis technologies helped in the creation of a 3D Structural model which helped in the generation of steel detailing drawings, connection detailing drawings, and structural frame layouts for the intended modules, guaranteeing precise representation of the project’s structure.

Building Services Design

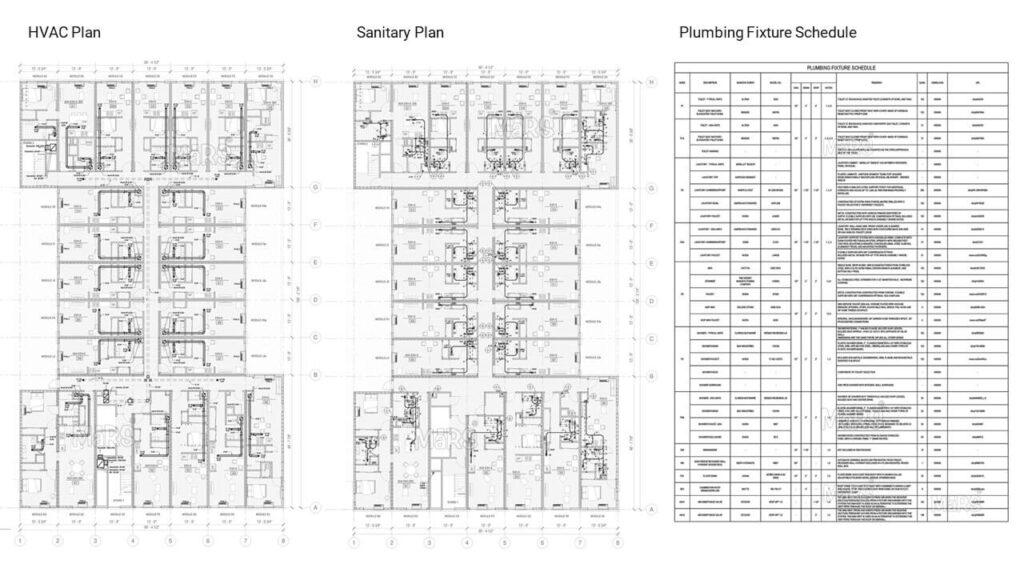

Building services cover a range of disciplines, including those needed for building operations after construction, such as HVAC, sanitary, electrical, and fire protection. To construct an MEP BIM model and link it to architectural and structural models for a complete BIM model, Revit MEP was used in conjunction with other tools. With the aid of tools for precise placement and annotation, components were placed and assigned to supply or return systems to model mechanical systems like HVAC duct systems, electrical systems like lighting fixtures and cable trays, and plumbing systems including plumbing fixtures schedule for each module.

Project Highlights

BIM Implementation Benefits for Elm Street Modular Construction

- Enhanced MEP Coordination: BIM is essential for off-site modular construction because it gives specialists a 3D representation of the building during the pre-construction phase. Before pre-fabrication design starts, BIM enables project managers to find potential conflicts in MEP systems, lowering the chance of conflicts.

- Limiting the growth of cost: Modular construction can save costs, but it can also increase expenses if initial planning is done incorrectly or the labor is underqualified. Organizations can discover the right collaborators, cut waste, and streamline operations with the use of BIM. According to a McKinsey study, BIM increases profits for 75% of construction firms.

- Increased Output and Productivity: Precast construction and off-site fabrication enhance concrete casting, lower high-volume labor costs, produce precise designs with no need for rework, and improve both productivity and cost. In high-performance building structures with BIM, proper implementation of prefab stimulates increased output, improved quality, and a higher return on investment.

- Improved project management using a common data environment: BIM helps collaborate and share information, coordinate activities across sites, and guarantee project completion on schedule. Bringing stakeholders together facilitates project completion by accelerating communication. For clearer, more precise communication, BIM serves as a common data environment.